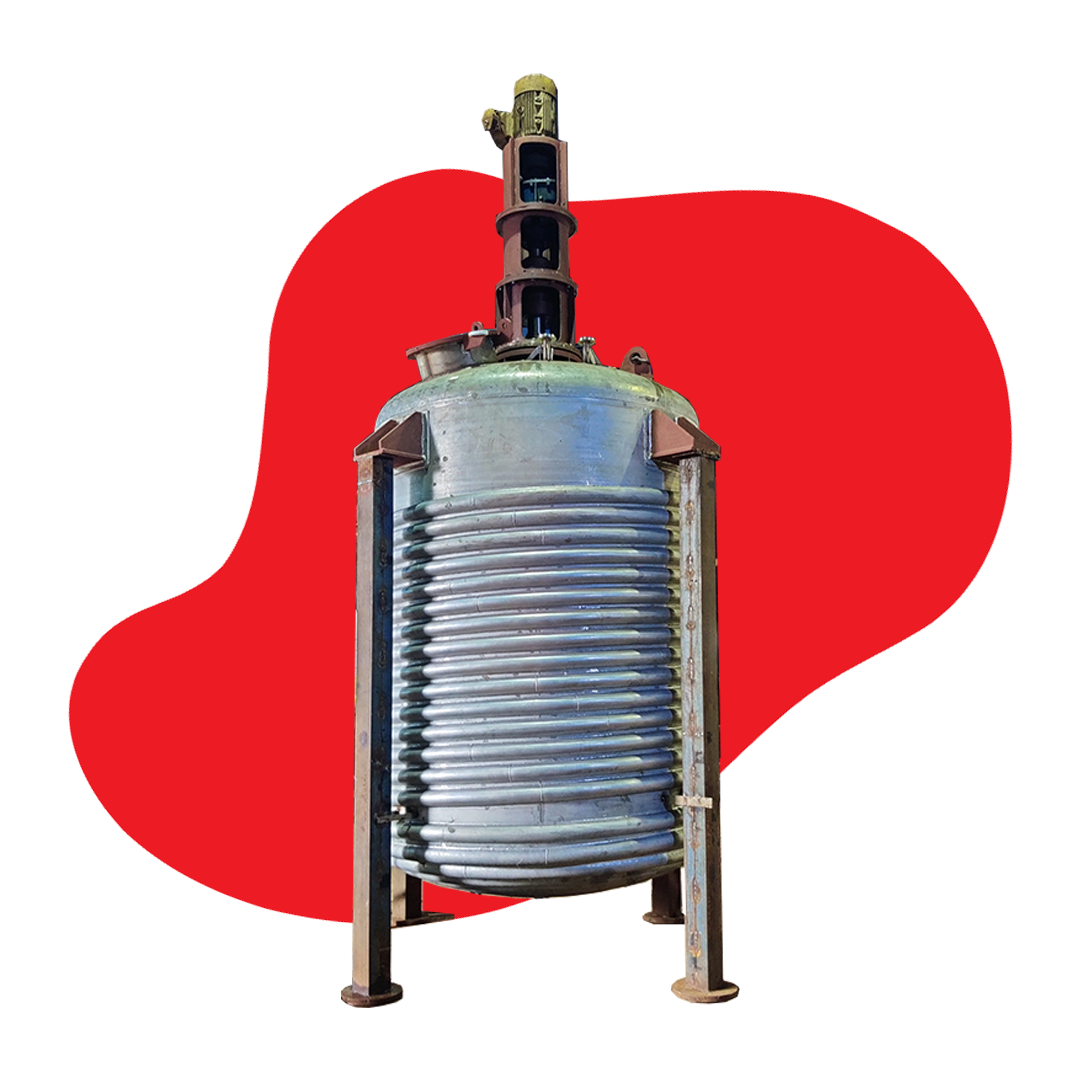

Maximize Uptime with Effective Rotary Vacuum Paddle Dryer Maintenance: Expert Tips

Keep your rotary vacuum dryer operating smoothly and efficiently with these key maintenance practices:

1. Visual Checks:

- Ensure no debris, tools, or leftover chemicals are present in the work area.

- Inspect for obstructions around the drive unit and rotating shaft.

- Check upstream and downstream components like valves, indicators, and dust collectors for proper operation.

- Regularly inspect and replace filter bags as needed.

2. Lubrication:

- Lubricate all designated parts, including gearbox, stuffing box, bearing, chain sprocket, and spur gear, with suitable lubricants

- Verify shaft concentricity and parallelity for mechanical seals before lubricating.

- Use only gasket sealants compatible with the processed product.

3. Static Testing:

- Conduct limpet, rotor (at rated pressure), and body pressure tests followed by a vacuum leak test.

4. Drive Testing:

- Manually turn the gearbox to check for internal obstructions.

- Gradually (inching) test the motor drive unit to verify proper direction.

- Ensure star-delta starting is used with a current monitoring system.

- Confirm no-load current matches manufacturer specifications.

5. Dry Running Trial:

- Perform a trial run without raw material, but including all utilities (hot/cold media, pneumatic, hydraulic pressure, and vacuum) to simulate actual operation.

Regular maintenance ensures your rotary vacuum paddle dryer performs optimally.

Ready to Maximize Your Dryer’s Efficiency?

Don’t wait for downtime to disrupt your operations! Request this detailed rotary vacuum paddle dryer maintenance checklist today. Let us help you maintain peak efficiency and prolong the lifespan of your RVD.

Other Resources

Looking for valuable insights and essential maintenance tips? Find our top resources here.