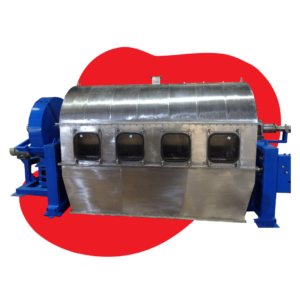

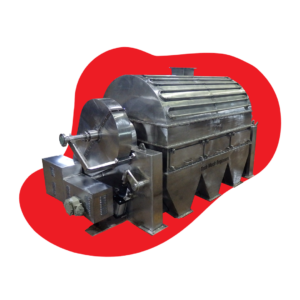

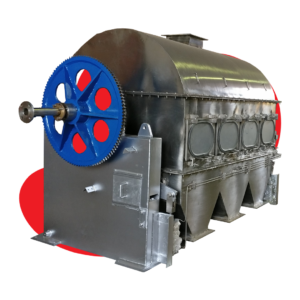

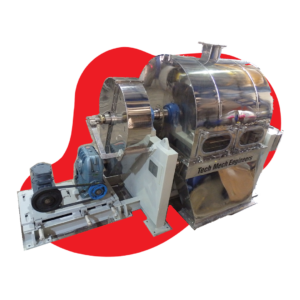

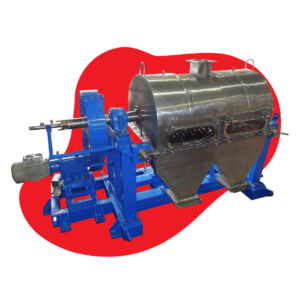

DRUM FLAKER

Drum Flakers (also known as flaker machine or rotating drum flaker) are an end-of-line equipment that are used in chemical manufacturing plants for phase conversion of molten liquid to solid flakes. Our drum flaker at Tech-Mech Engineers is designed for flexibility, with customizable features to meet your specific processing requirements. From the size and shape to the materials and control systems, we can tailor the system to your exact needs.

Industry Applications

Product Details - Drum Flaker

-

Product Information

-

Working Mechanism

-

Technical Specifications

-

Features

-

Advantages

-

Accessories

Drum Flakers, also known as flaker machines or rotating drum flakers, play a crucial role in chemical manufacturing plants for converting molten liquids to solid flakes. At Tech-Mech Engineers, we offer durable, reliable, and automated Drum Flakers that run 24/7 to ensure uninterrupted production. Our flakers are available in various specifications and can be further customized to meet your specific requirements, with sizes ranging from 0.75 sq.m to 25 sq.m and materials including camphor.

Our experienced professionals design the Drum Flakers using high-quality components and advanced technology to ensure efficient and reliable performance. We provide pneumatically operated blades, knockers, control valves, and a fully functional electrical panel for a plug-and-play system. We also offer after-sales service and commissioning at the site to ensure hassle-free operation.

At Tech-Mech Engineers, we understand the importance of uninterrupted production in chemical plants. Therefore, we have a trial machine at our factory to optimize the size and kg/hr output for your material, ensuring zero downtime for your production. Once all operating parameters are set, our Drum Flaker guarantees flawless production of every single batch. Choose Tech-Mech Engineers for customized and reliable Drum Flakers that meet your specific needs.

In addition to manufacturing customized drum flakers, we also provide after-sales support and commissioning services at the site.

The drum flaker is a continuous process equipment used for converting molten liquid to solid flakes in chemical manufacturing plants. It operates by dipping the external surface of a rotating drum into molten liquid while continuously spraying the internal drum surface with a cooling medium. The cooling medium cools the internal surface of the drum and the molten product by conduction, causing it to solidify. The solid material obtained from this process is then scraped on the other side with a suitable scrapping knife edge, resulting in random size flakes that are sufficiently cool enough to be handled manually.

The drum flaker is designed with a completely enclosed and covered structure, which prevents any dust from being introduced into the product. This also ensures the safety of the operator from fumes and heat. The water collected during the cooling process is removed using the air siphoning principle.

This efficient process ensures continuous production with minimum manual intervention, ensuring maximum output and minimal downtime. The drum flaker is designed for durability, with top-quality components and materials used in its construction. Its customizable features allow it to be tailored to meet the specific requirements of any chemical manufacturing plant, making it an ideal end-of-line equipment for phase conversion of molten liquid to solid flakes.

- Type: Continuous rotating drum flaker

- Operating mode: Batch or continuous operation

- Drum diameter: Customizable, typically ranges from 0.5 m to 2 m

- Drum length: Customizable, typically ranges from 0.8 m to 4 m

- Drum surface: Machined polished surface

- Cooling media: Cooling Water, Chilled Water or Brine

- Scraper mechanism: Suitable scraper knife edge

- Flake size: Random, typically ranging from 0.5 mm to 5 mm thickness

- Capacity: Customizable, typically ranges from 50 kg/hr to 3,000 kg/hr

- Construction material: Stainless steel, or other materials as per customer’s requirements

- Electrical requirements: 3-phase, 440V, 50Hz

- Control system: PLC-based control system with HMI

- Safety features: Enclosed design to prevent dust and fumes, emergency stop button, overload protection, etc.

Note that these specifications can vary depending on the specific requirements of the customer and the product being processed.

- Low maintenance requirements

- High efficiency for improved productivity

- Precisely engineered and compact for optimized performance

- Automatic operation for ease of use

- Enclosed cooling system to prevent cross-contamination and ensure product quality

- Cost-effective operation with low maintenance costs

- Gas-tight enclosure for maximum safety and protection

- Easy access for maintenance and cleaning purposes

- Consistent output of high-quality flakes in terms of weight and thickness.

With our Drum flaker, you can enjoy the following benefits:

- Customizable design to optimize the size and kg/hr output for your material, thanks to our trial machine at our factory.

- Manufactured GMP model Flakers for challenging materials such as Camphor, ensuring efficient processing of a wide range of materials.

- Pneumatically operated blades, knockers, and control valves for automatic operation, reducing the need for manual intervention.

- Fully functional electrical panel for a plug-and-play system, allowing for easy installation and startup.

- After-sales service and commissioning at site included in our scope, ensuring smooth operation of the flaker and maximum uptime.

- Easy maintenance and cleaning, thanks to our unit design with proper access.

- Consistent output in terms of quality, weight, and thickness of flakes, ensuring reliable and high-quality processing of your materials.

In addition to the standard features of our Drum Flaker, we offer a range of accessories to enhance your operation and meet your specific requirements. These include:

Pneumatically operated blades: Our flakers come equipped with high-quality blades that are pneumatically operated, ensuring precise and efficient flaking of the material.

Knockers: Our flakers are designed to handle a wide range of materials and to prevent clogging, we provide knockers to dislodge any material that may get stuck during the flaking process.

Control valves: To ensure that the cooling media is sprayed uniformly and accurately onto the internal surface of the drum, we provide high-quality control valves that are easy to operate and maintain.

Electrical panel: Our flakers come equipped with a fully functional electrical panel, which is designed to provide reliable and efficient operation. The panel is easy to operate and features a user-friendly interface.

All of these accessories are included with our flakers as part of our plug-and-play system. This ensures that our customers receive a complete solution that is ready to be installed and commissioned at their facility. Additionally, we offer after-sales services and commissioning at the site to ensure that our customers receive the support they need to operate and maintain their flaker.

Tailored Drum Flaker for Your Processing Needs

At Tech-Mech Engineers, we understand that every processing requirement is unique. That's why we offer a customizable drum flaker with flexible features that can be tailored to your specific needs. From materials and size to control systems, we provide a solution that meets your processing requirements with precision.

Other products

With our cutting-edge technology and skilled workforce, we guarantee the highest level of quality in all our products.