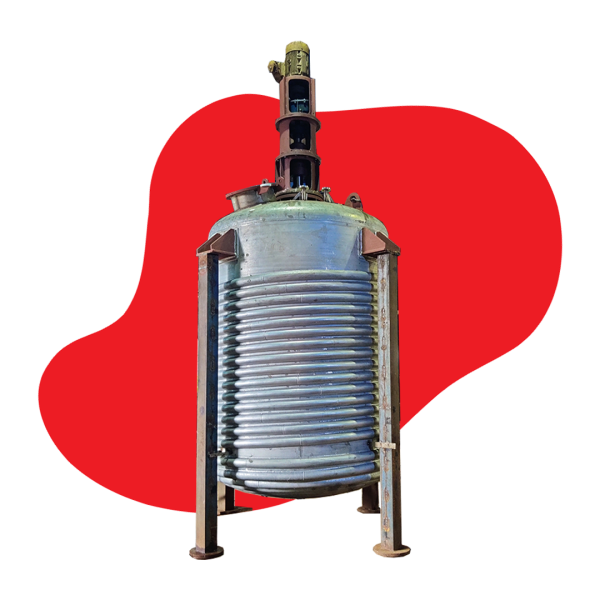

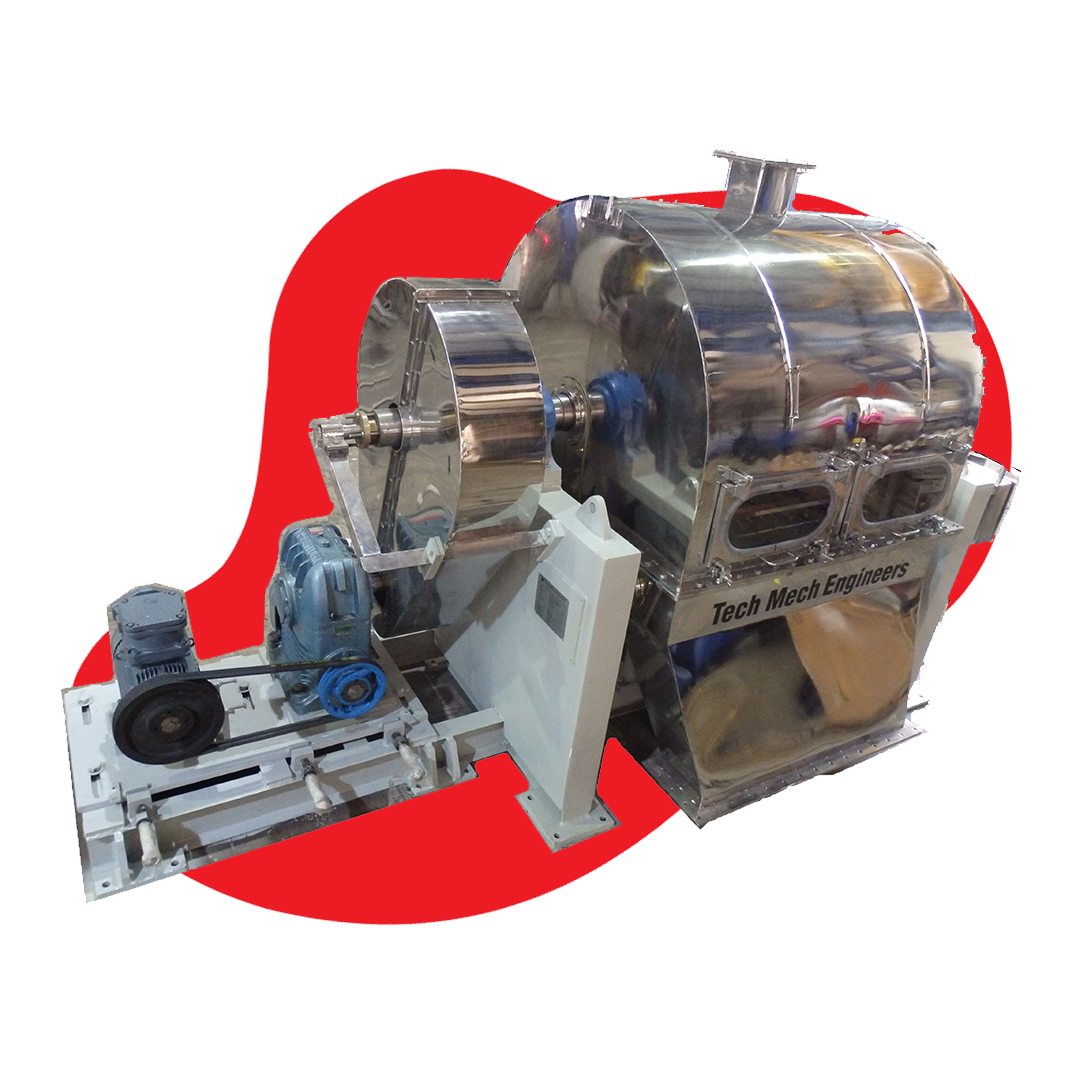

Agitators | Reactors

Agitators | Reactors are essential components in mixing and blending processes, ensuring uniform distribution of substances within the reactor vessel. At Tech-Mech Engineers, we offer a range of high-quality Agitators | Reactors, resulting in optimized performance and product quality. Our Agitators | Reactors are customizable to meet specific application requirements, allowing for efficient mixing of a variety of materials, including those that are viscous, abrasive, or have unique flow properties.

Industry Applications

Product Details - Agitators | Reactors

-

Product Information

-

Working Mechanism

-

Technical Specifications

-

Features

-

Advantages

-

Accessories

Agitators are essential equipment used in the mixing and blending of various substances in many industries, including oil and gas, pharmaceuticals, specialty chemicals, and more. Tech-Mech Engineers offers a wide range of high-quality agitators that are engineered to meet your specific mixing requirements.

Our Reactors come in various sizes and designs, including top-entry and side-entry, and can be customized to suit your specific application needs. We use different types of impellers, including axial flow, radial flow, and mixed flow, to achieve the required mixing and blending effects.

Our agitators are designed to handle high-temperature operations and can be constructed using materials such as SS304, SS316, SS317, S310, SS321, 904L, C2205, C2206, Inconel, C22, and C276. They are available in both limpeted and jacketed configurations to enhance heat transfer efficiency.

We offer several types of shaft sealing options, including single mechanical seal, double mechanical seal, and stuffing box, to ensure that our agitators are leak-proof and safe. Additionally, our agitators are equipped with features such as shaft balancing and double taper roller bearings, which ensure smooth and efficient operation.

Our agitators are available in GMP models, making them suitable for use in the pharmaceutical industry. They are also designed to work in tandem with our reactors, ensuring optimal performance and consistency in your mixing operations.

Agitators are machines that are used to mix, blend or stir fluids or powders in a tank or vessel. They are commonly used in the chemical, pharmaceutical, food and beverage, and water treatment industries, among others. The basic working principle of an agitator is to create turbulence in the fluid or powder being mixed, in order to promote uniform distribution of the components and enhance the reaction or mixing rate.

Agitators typically consist of a rotating shaft, which is driven by an electric motor or other power source. Attached to the shaft are one or more blades, which are shaped and positioned to create different types of fluid flow patterns in the tank. The blades can be flat, curved, pitched, or other shapes, depending on the specific mixing requirements.

The agitator’s operation can be controlled by adjusting the speed and direction of rotation of the shaft, as well as the position and shape of the blades. For instance, a low-speed, high-torque agitator may be used to promote gentle mixing and prevent the formation of air bubbles or foam, while a high-speed, high-shear agitator may be used to break down solids or emulsify liquids.

In addition, agitators may be equipped with various types of sealing systems, depending on the properties of the fluid being mixed and the level of containment required. For example, mechanical seals, lip seals, or packing seals may be used to prevent leakage and maintain the integrity of the system.

Overall, the working mechanism of an agitator involves the creation of controlled fluid motion and mixing, using a rotating shaft and blades, in order to achieve the desired chemical, physical, or biological process.

- Type of agitator: Various types of agitators are available, including propeller, turbine, anchor, paddle, and others.

- Material of construction: SS304, SS316, SS317, S310, SS321, 904L, C2205, C2206, Inconel, C22, and C276.

- Shaft diameter: Available in various diameters depending on the size and type of agitator.

- Number of blades: Varies depending on the type of agitator.

- Blade shape: Varies depending on the type of agitator.

- Shaft speed: Adjustable depending on the application.

- Motor power: Available in various power ratings depending on the size and type of agitator.

- Mounting type: Available in various mounting configurations, including top, bottom, and side entry.

- Sealing type: Available in various sealing types, including single or double mechanical seals, packing, and others.

Please note that these technical specifications can vary depending on the specific type and model of agitator being used.

- High mixing efficiency, ensuring uniform mixing of materials

- Customizable impeller and shaft designs to suit specific mixing requirements

- Versatility in handling various viscosities and densities of materials

- Precise speed control to optimize mixing performance

- Multiple options for agitator mounting, including top, side, and bottom entry

- Easy installation and maintenance with simple, robust design

- Compatibility with a range of vessel sizes and shapes

- Wide range of materials of construction available, including stainless steel, carbon steel, and exotic alloys

- Options for heating or cooling through the agitator shaft for efficient temperature control

- Various sealing options available to suit different process requirements

- Compliance with industry standards and regulations.

With our Agitators, you can enjoy the following benefits:

- High mixing efficiency, ensuring uniform mixing of materials

- Customizable impeller and shaft designs to suit specific mixing requirements

- Versatility in handling various viscosities and densities of materials

- Precise speed control to optimize mixing performance

- Easy installation and maintenance with simple, robust design

- Compatibility with a range of vessel sizes and shapes

- Wide range of materials of construction available, including stainless steel, carbon steel, and exotic alloys

- Options for heating or cooling through the agitator shaft for efficient temperature control

- Various sealing options available to suit different process requirements

- Compliance with industry standards and regulations.

Here are some accessories that can be used with an agitator:

- Speed Controllers: Speed controllers allow for precise control of the agitator’s speed, ensuring optimal mixing performance and consistency.

- Variable Frequency Drives (VFDs): VFDs can be used to vary the speed of the agitator motor, allowing for more flexible and efficient operation.

- Motorized Lift Systems: Motorized lift systems make it easy to adjust the height of the agitator for different process requirements, making it more versatile and efficient.

- Sealing Systems: Sealing systems can be used to prevent leakage from the agitator shaft, ensuring operator safety and preventing contamination of the product.

- Heating or Cooling Jackets: Agitators can be equipped with heating or cooling jackets to control the temperature of the material being mixed, ensuring consistent and precise results.

- Control Panels: Control panels can be used to monitor and control the operation of the agitator, providing operators with real-time information about the process and allowing for quick and easy adjustments as needed.

- Shaft Extension: Shaft extensions can be added to the agitator to increase the depth of mixing, ensuring thorough mixing of the material being processed.

- Customized Impeller Design: Customized impeller designs can be used to optimize mixing performance for specific materials and process requirements.

Customizable Agitators | Reactors for Your Unique Mixing Needs

At Tech-Mech Engineers, we understand that every mixing process is unique and requires tailored solutions. That's why we offer a range of customizable agitators to meet your specific mixing needs. With our expertise in impeller and shaft design, we can provide optimal mixing performance for various viscosities and densities of materials. Our agitators can be mounted from the top, side, or bottom, and we offer a wide range of materials of construction, including stainless steel, carbon steel, and exotic alloys.

Other products

With our cutting-edge technology and skilled workforce, we guarantee the highest level of quality in all our products.