Column & Column Internals

Discover durable stainless steel Distillation Columns and Column internals for industrial applications. Our corrosion-resistant stainless steel columns ensure efficient separation and purification processes. Choose from a variety of sizes and configurations to meet your specific needs. Enhance productivity and reliability with our high-quality stainless steel solutions

Industry Applications

-

Product Information

-

Working Mechanism

-

Technical Specifications

-

Features

-

Advantages

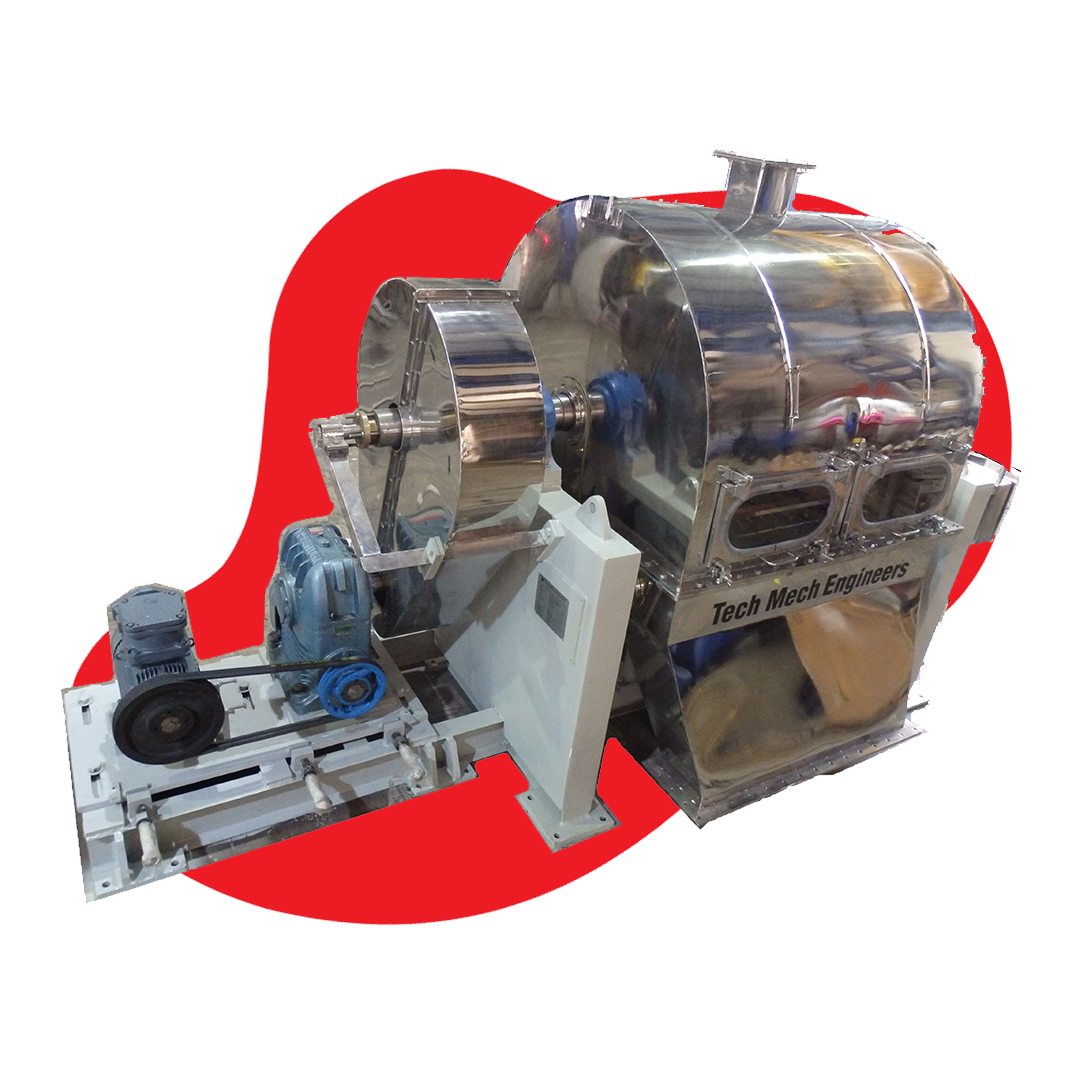

Tech Mech Engineers specializes in high-quality Industrial Columns for diverse distillation processes. Our reliable columns, including Simple Distillation, Steam Distillation, Fractional Distillation, and Vacuum Distillation, offer efficiency and minimal downtime.

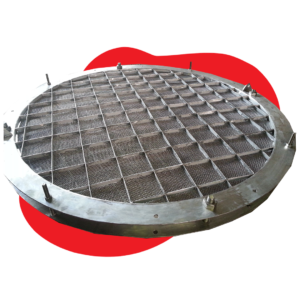

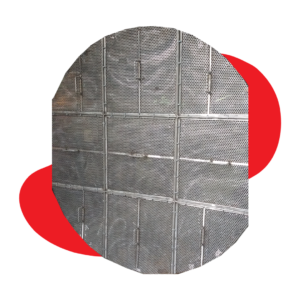

Column internals can be provided from Random Packing (Raschig Ring, Pall Ring, Imtp Saddle) and Structure Packing (Wire Mesh, Bubble Caps, Perforated Tray) internals to optimize separation and distribution.

Our columns range from 3″ lab models to 3-meter diameter columns, with options for spray and distribution nozzles. We use materials like SS304, SS316, SS317, S310, SS321, 904L, C2205, C2206, Inconel, C22, and C276 for durability.

With QAP manufacturing, including material testing, radiography, dye penetrant testing, ultrasonic testing, and inspection reports, our columns assure traceability.

Pharmaceutical-grade GMP models are also available. Tech Mech Engineers delivers cost-effective solutions, optimized for temperature and pressure ranges, ensuring reliable performance. Elevate your distillation processes with our dependable Industrial Columns and Column Internals.

Distillation column, is a widely used chemical process unit for efficient separation of multicomponent mixtures.

Columns play a crucial role in traditional chemical engineering, especially in the oil and gas industry. Distillation leverages heat application and removal to exploit differences in relative volatility, enabling the vaporization of components with lower boiling points.

This process facilitates the separation of mixtures based on their relative volatilities. Whether it’s binary or multi-component mixtures, distillation offers effective separation techniques.

Specialized columns like reactive distillation units that combine reaction and product separation. Optimize energy consumption and separation performance by understanding the optimal sequencing of distillation columns in industrial processes. Trust in the reliability and efficiency of Tech Mech Engineers distillation columns for various liquid-liquid separation needs.

- Vessel size: Available in a wide range of sizes, from 3” to 3-meter Diameter

- Vessel design: For Seismic and Wind Loads, with multiple internal structure

- Material of construction: SS304, SS316, SS317, S310, SS321, 904L, C2205, C2206, Inconel, C22, and C276.

- GMP models: Available.

- Operating temperature: Suitable for high-temperature operations.

- Operating pressure: Suitable from Vacuum to high pressure operations

- Column Internals: Raschig Ring, Pall Ring, Imtp Saddle, Wire Mesh, Bubble Caps, Perforated Tray

- Manufacturing: Specialised process of Laser Cutting, CNC Bending, pressing, lathe are used.

- Please note that these technical specifications can vary depending on the specific type and model of reactor being used.

- High efficiency for complete and uniform mixing of materials

- Customizable design options for agitators, baffles, and impellers to meet specific mixing requirements

- Versatility in handling various chemical and physical properties of materials

- Precise temperature control for optimal chemical reactions

- Multiple options for reactor mounting, including vertical or horizontal installation

- Easy installation, operation, and maintenance with a simple, robust design

- Compatibility with a range of vessel sizes and shapes

- Wide range of materials of construction available, including stainless steel, carbon steel, and exotic alloys

- Options for heating or cooling through the reactor jacket or coils for efficient temperature control

- Various sealing options available to suit different process requirements

- Compliance with industry standards and regulations, including ASME, PED, and CE certifications.

With our Columns and Column Internals, you can enjoy the following benefits:

- Versatility in handling various viscosities and densities of materials

- Easy installation and maintenance with simple, robust design

- Compatibility with a range of vessel sizes and shapes

- Wide range of materials of construction available, including stainless steel, carbon steel, and exotic alloys

- Various sealing options available to suit different process requirements

- Compliance with industry standards and regulations.

Customizable Columns & Column Internals to Meet Your Unique Process Requirements

At Tech-Mech Engineers, we understand that every process is unique, which is why we offer a range of customization options for our industrial Distillation Columns and Column Internals. From material of construction to configuration, our team can work with you to design a Column that meets your specific requirements. Whether you need a Column for high-pressure applications or low-temperature processes, we have the expertise to deliver a solution that meets your needs. With our customization options, you can optimize your process and improve efficiency.

Product Details - Column & Column Internals

Other products

With our cutting-edge technology and skilled workforce, we guarantee the highest level of quality in all our products.