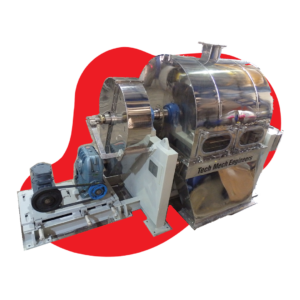

Essential Drum Flaker Maintenance: Top Tips & Practices

Flakes flying off the production line? Ensure optimal performance and uptime with these key flaker maintenance practices.

1. Visual Checks:

- Inspect the drum surface for wear or damage.

- Clear away debris, leftover chemicals, and unnecessary tools.

- Clean the material tray using appropriate methods like steam, manual scraping, or material remelting.

- Remove any material buildup behind the scraper and in the chute/hopper system.

- Check for accumulated dry product around the unit.

2. Lubrication:

- Apply suitable lubricants to the gearbox, chain sprockets, bearings, and scraper plummer block.

3. Static Testing:

- Conduct limpet pressure, pneumatic line pressure, and hydraulic line pressure tests.

- Test the siphon system for proper functionality.

- Verify the cooling media flow rate, as it impacts overall cooling efficiency.

- If insufficient, consider drum opening and flushing for cleaning.

4. Drive Testing:

- Manually rotate the gearbox to check for internal obstructions.

- Gradually test the motor drive unit to confirm proper direction (inching).

- Ensure star-delta starting is used with a current monitoring system.

- Verify no-load current matches manufacturer specifications.

5. Dry Running Trial:

- Perform a trial run with raw material to ensure the drum operates in the correct direction.

- Verify optimal utility levels before final operation.

- Insufficient cooling can lead to significant performance losses.

Regular maintenance ensures your drum flaker performs optimally.

Ensure Optimal Performance with Regular Drum Flaker Maintenance

For a detailed drum flaker maintenance checklist, contact us today. Let us help you maintain peak efficiency and prolong the lifespan of your flaker.

Other Resources

Looking for valuable insights and essential maintenance tips? Find our top resources here.