Heat exchanger

A heat exchanger is a highly efficient and essential device used to transfer heat between fluids without mixing them. It is widely used in industrial and commercial applications to increase efficiency and save energy. And especially useful for applications involving heat-sensitive materials or highly viscous fluids where other methods of heat transfer may not be suitable. Our heat exchangers are designed to maintain high accuracy during bundling and welding, allowing for minimum distortion to the equipment.

Industry Applications

Heat Exchanger - Product Details

-

Product Information

-

Working Mechanism

-

Technical Specifications

-

Features

-

Advantages

-

Accessories

-

Types of heat Exchangers

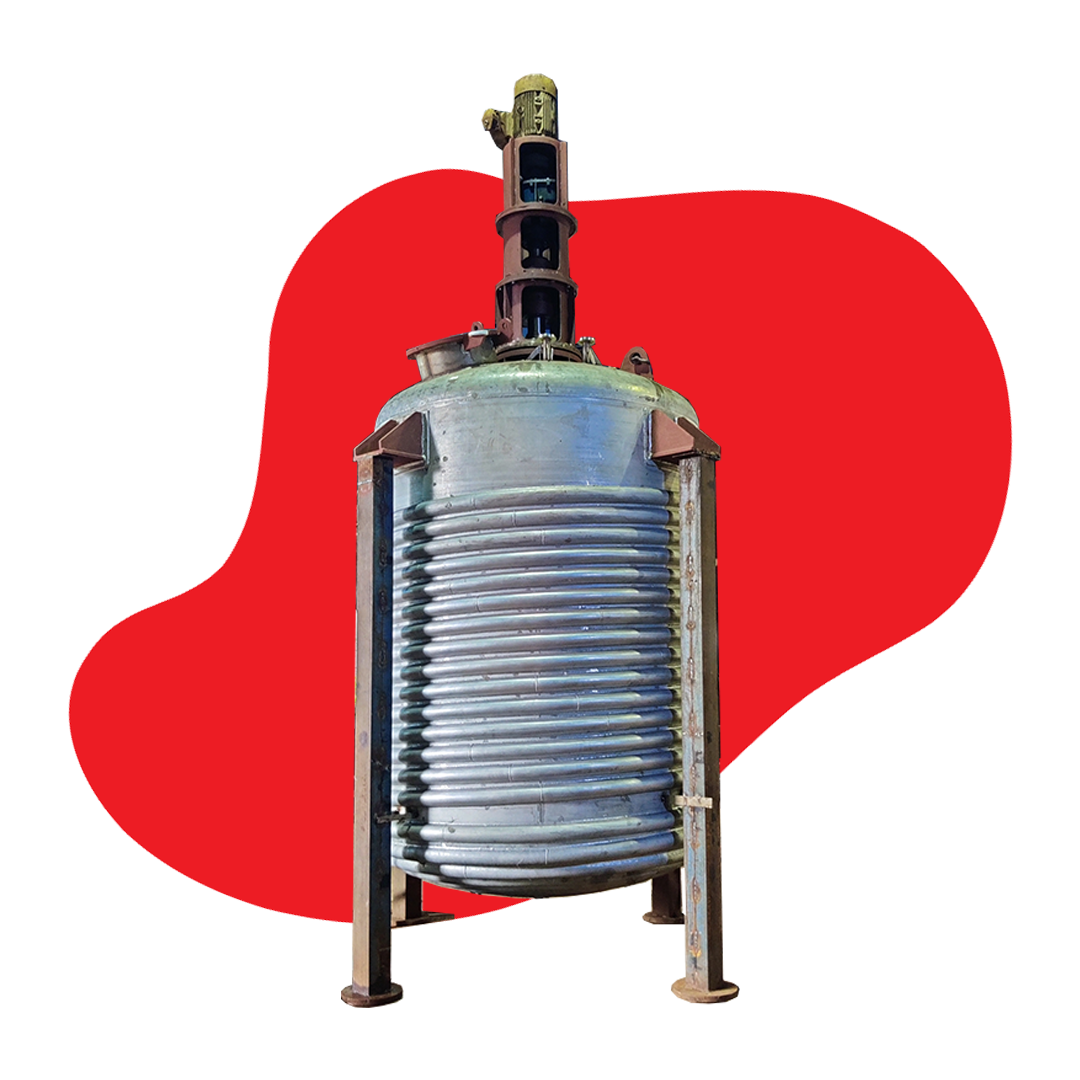

The Heat Exchanger is a versatile solution for various industries that require efficient heat transfer and precise temperature control. At Tech Mech Engineers, we offer a sturdy and reliable design that maximizes heat transfer and ensures optimal performance.

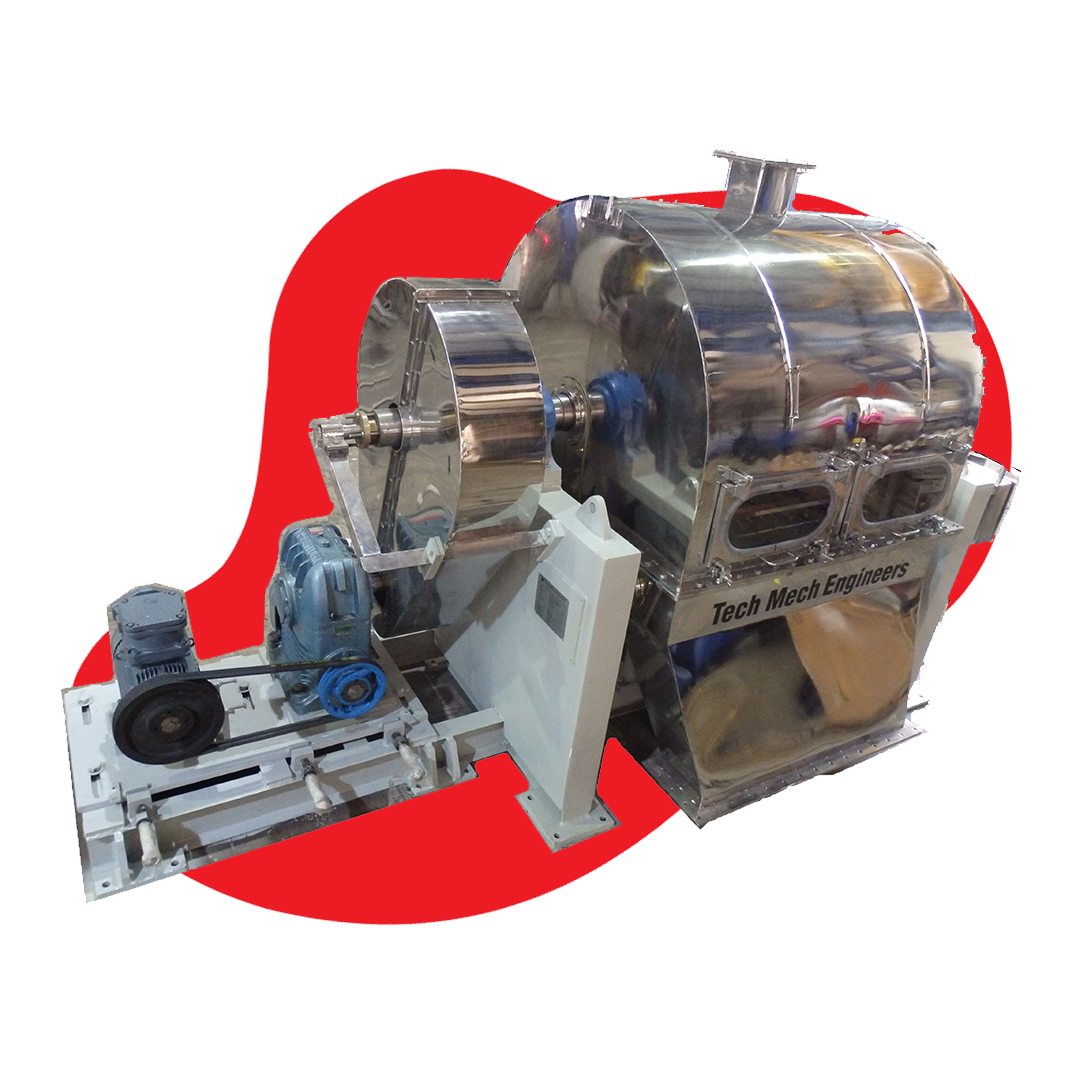

Our HE’s is available in both vertical and horizontal configurations, making it easy to customize to your specific process needs. With a wide range of HTA’s available, we can ensure that the Shell Body is suitable for limited spaces when large HTA is required, optimizing space efficiency. For High Temperature Range Exchanger single bellow to multiple expansion bellows are available, and straight tube & U-Tubes configurations, providing you with flexibility and versatility.

Installation of our Heat Exchanger is Plug and Play Type, with ease of installation being a key feature. Our Design features sturdy bundling and welding for minimal equipment distortion, reducing maintenance costs. We also offer tube replacement services to ensure that your operation is always performing at its best.

At Tech Mech Engineers, we understand that every customer has unique requirements, which is why we offer customized solutions to meet your specific needs. Whether you require a large or small exchange area application, we can provide you with a solution that maximizes efficiency and reduces costs.

In addition, we also offer a range of accessories such as pressure vessels, expansion bellows, Tube Bundles and tube sheets. Our accessories are designed to work seamlessly with our Heat Exchanger, providing you with a complete solution for your heat transfer needs.

Heat exchangers transfer thermal energy between two fluids without allowing them to mix. One fluid flows through a set of tubes, while the other passes around the tubes, separated by a heat-conducting wall. The heat flows from the warmer fluid to the cooler one, resulting in a transfer of thermal energy.

HE’s use a variety of designs and technologies to optimize thermal efficiency and durability.

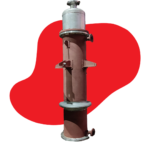

Shell and Tube Design: This design features a bundle of tubes enclosed in a cylindrical shell, with one fluid flowing through the tubes and the other around the outside. This design is versatile and can be used for a wide range of applications.

Exchangers are designed to provide optimal thermal efficiency and durability, ensuring that your system operates at peak performance for years to come. Whether you require for a specific industrial process or Chemical process, there is a range of designs and technologies to suit any application.

- Type: Shell and Tube or U Tube

- Configuration: Vertical or horizontal

- Tube Design: Straight tubes or U-tubes

- Tube Expansion: Single bellow to multiple expansion bellows

- Pass Design: Single pass to multiple pass

- Tube Replacement Services: Available

- Material: SS304, SS316, SS317, 904L, C2205, C2206, C22, C276

- Weight: up to 25Tons

- Heat Transfer Area (HTA): As per reqquirements

- Maximum Design Pressure: As per client requirements

- Maximum Operating Temperature: As per client requirements

Note: The specifications will vary based on the specific requirements of the client and application. We maintain high accuracy during bundling and welding to minimize distortion to the equipment. In addition to Shell and Tube Heat exchangers, we have also manufactured Falling-Film Evaporators with a distributor arrangement on top, and can manufacture Heat Exchangers up to 1000 sq.m in size. Please contact us for more information about our heat exchangers and services.

- High thermal efficiency for optimized heat transfer

- Precise temperature control for process optimization

- Vacuum operation for better handling of heat-sensitive materials

- Efficient tube expansion for maximum heat transfer

- Vertical and horizontal configurations for space optimization

- Single bellow to multiple expansion bellows for high temperature design optimization

- Straight tube & U-Tubes for customization to process needs

- Single pass to multiple pass design for increased efficiency

- Direct contact large flow rates for efficient heat transfer

- Low pressure drops for energy efficiency

- High operating pressure and large design sizes for versatility

- Available in a wide range of HTA’s for customization

- Ease of installation for quick and easy setup

- Suitable for limited space when large HTA is required, optimizing space efficiency

- Durable and reliable for long-lasting performance.

- Sturdy bundling and welding for minimal equipment distortion

- Tube replacement services available for maintenance and repair

With our Heat Exchanger, you can enjoy the following benefits:

- Versatile design that can be customized to meet your process needs, with options such as vertical and horizontal configurations, single bellow to multiple expansion bellows, and straight tube & U-Tubes.

- Flexibility to accommodate limited spaces and a wide range of HTA’s, providing you with a solution tailored to your specific requirements.

- Quick and easy installation, allowing you to set up and start using your Heat Exchanger with minimal effort and downtime.

- Reduced maintenance costs, thanks to sturdy bundling and welding that minimizes equipment distortion, and tube replacement services available for maintenance and repair.

- Long-lasting and reliable performance, giving you increased operational uptime and peace of mind.

Accessories:

- Gaskets: From CNAF to Metal gaskets to ensure a leak-free performance

- Flanges: SORF, WNRF, and Double Groove flanges for easy installation and maintenance

- Insulation: Customized insulation for heat retention and energy efficiency

- Support structures: Durable support structures for proper installation and stability

- Valves: Operational Valves and Safety valves for efficient and safe flow control

- Piping: Customized piping for seamless integration into existing systems

- Instrumentation: Precision instrumentation for accurate monitoring and control of heat exchange processes.

Note: The specific accessories offered may vary depending on the Heat Exchanger model and customization requirements.

- Shell and Tube

- U-Tube Bundle

- Cooling Coil Type

- Pipe In Pipe

- Kettle Reboiler

- Split Flow Evaporators

- Condenser

- Reboiler

- Falling Film Evaporators

- Floating head (Pharma)

Custom Heat Exchangers for Your Unique Requirements

At Tech Mech Engineers, we understand that every industry and process has unique heat transfer needs. That's why we offer a wide range of customization options for our heat exchangers, including vertical and horizontal configurations, single bellow to multiple expansion bellows, and straight tube & U-Tubes. With a variety of HTA's available and the ability to handle granular and pasty materials, our Heat Exchangers can be tailored to your specific requirements, ensuring optimal performance and efficiency. Contact us today to discuss your custom Heat Exchanger needs.

Other products

With our cutting-edge technology and skilled workforce, we guarantee the highest level of quality in all our products.