Pressure Vessels

Pressure vessels are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. They are commonly used in various industries for processes such as chemical reactions, heat transfer, and storage of compressed gases. Our equipment are built to meet the highest safety standards and can be customized to fit your specific application requirements.

Industry Applications

Product Details - Pressure Vessels

-

Product Information

-

Working Mechanism

-

Technical Specifications

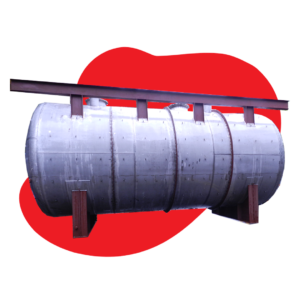

Our pressure vessels are designed to meet a wide range of needs and applications, providing reliable and efficient operation in a variety of industries. Available in sizes ranging from 50L to 50KL and weighing up to 20 tons, our vessels are built with Industry Standard materials and qualified manufacturing practice to ensure maximum durability and longevity.

Our Vessels are available in a GMP model with dairy and pharma finishes for sanitary applications, making them suitable for use in a variety of industries, including food and beverage, pharmaceuticals, and biotech. They are also suitable for use as storage tanks or for industrial processes such as chemical reactions and holding vessels

Our equipment can be customized with hot/cold jackets and continous coil limpets to meet specific heating or cooling requirements, as well as with internal cooling coils for efficient temperature control. The vessels are designed for easy maintenance and minimal downtime, with zero maintenance costs.

Our pressure vessels are built with Tori-spherical, Ellipsoidal, or Spherical dish ends in petal construction, depending on the application. They are suitable for use as lab equipment or product equipment, depending on the needs of the user.

A pressure vessel (also known as chemical vessel) is a closed container designed to hold gases or liquids at a pressure that is different from the ambient pressure. The working mechanism of a pressure vessel involves the application of external pressure to the contents of the vessel, which causes the pressure inside to increase. The pressure can be generated using various methods, including pumps or compressed gases.

The equipment is designed to withstand the resulting pressure and prevent any leaks or ruptures. The strength and integrity of the vessel are maintained through the use of industry standard materials and careful design and construction techniques.

There is wide application range, including storing and transporting gases and liquids, as well as for various industrial processes such as chemical reactions and storage. The vessel are designed and constructed to meet various safety and regulatory standards to ensure that it can operate safely and reliably under the intended conditions.

- Capacity: 50 liters to 1,00,000 liters

- Weight: up to 25 tons

- Models: GMP (Good Manufacturing Practice) compliant for pharmaceutical and dairy industries

- Finish: Dairy and Pharma Finish

- Multiple Start Limpets and Jackets

- Construction: Tori dishend, Elliptical dishend, and Spherical dishend in petal construction

- Material of construction: SS304, SS316, SS317, S310, SS321, 904L, C2205, C2206, Inconel, C22, C276, SA516 Gr70

- Pressure rating: Client Requirement

- Temperature rating: Client Requirement

- Welding: ASME Section IX, AWS D1.1, TIG/MIG welding

- Testing: Hydro testing, Radiography, Dye-penetrant testing, Ultrasonic testing

Customization Options for Pressue Vessels

At Tech-Mech Engineers, we offer a range of customization options to tailor our pressure vessels to your specific requirements. Choose from various sizes, materials, finishes, and accessories to ensure optimal performance for your application.

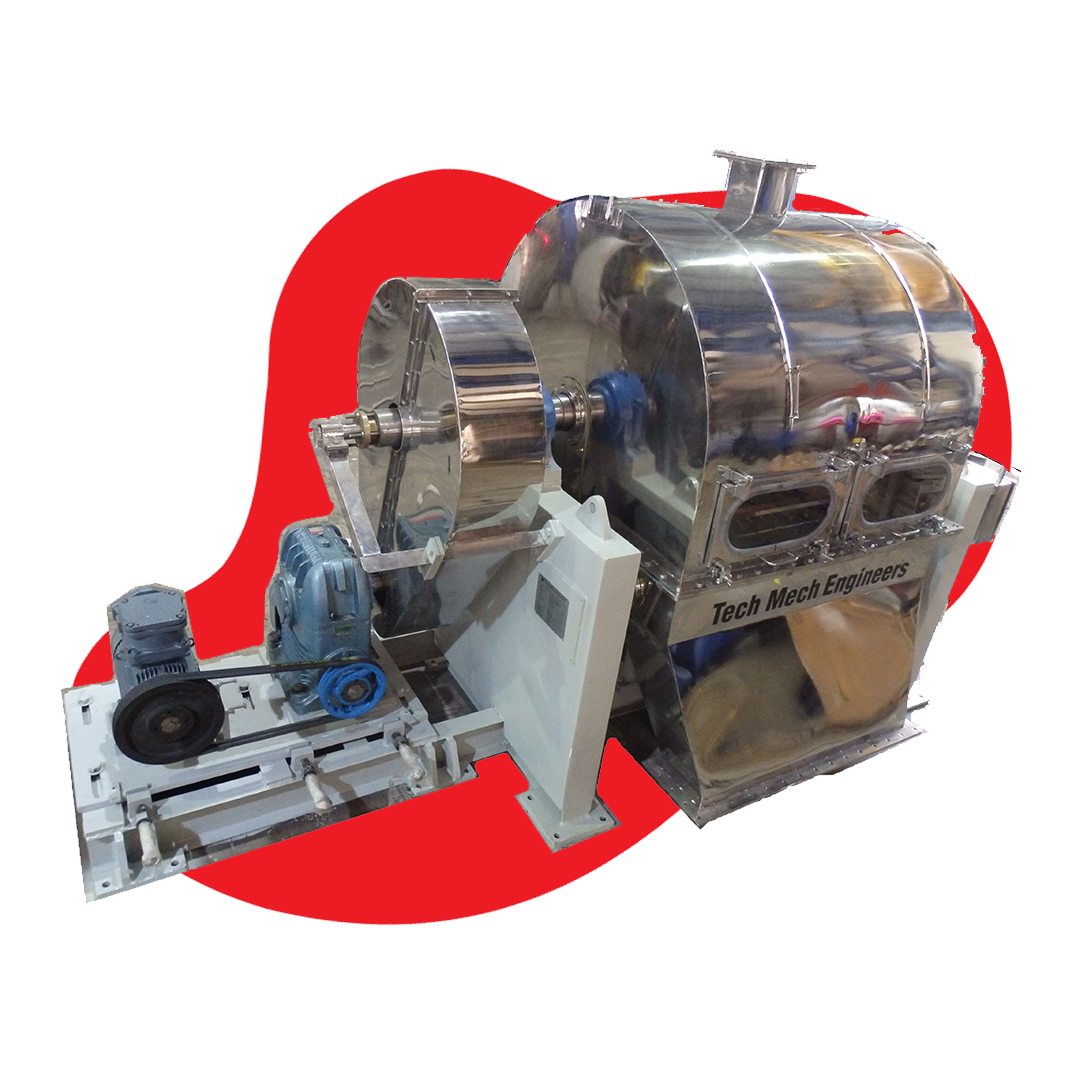

Other products

With our cutting-edge technology and skilled workforce, we guarantee the highest level of quality in all our products.