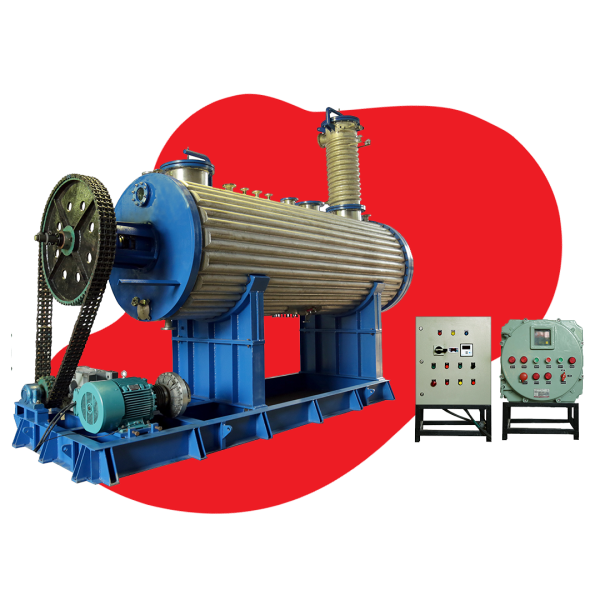

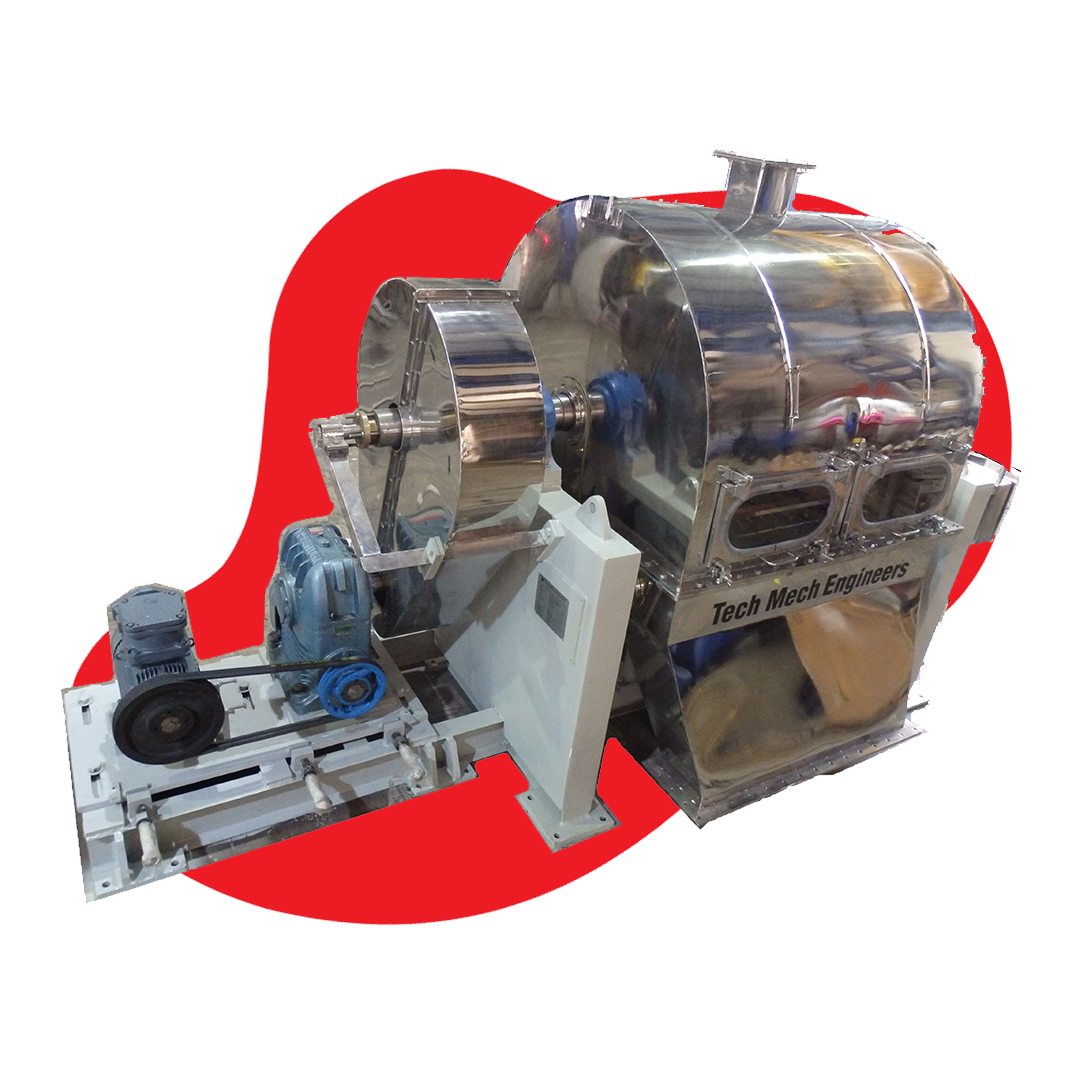

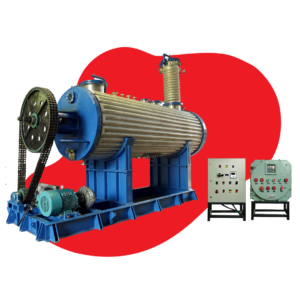

Rotary Vacuum Dryer

The Rotary Vacuum Dryer is a highly efficient solvent recovery / drying solution that uses a vacuum to remove moisture / solvent from materials. It is ideal for processing heat-sensitive and highly viscous materials, producing a uniform final product without any product degradation. Our Rotary Vacuum Dryers are available in a range of sizes and configurations to suit various applications and can be customized to meet your specific needs.

Industry Applications

Product Details - Rotary Vacuum Dryer

-

Product Information

-

Working Mechanism

-

Technical Specifications

-

Features

-

Advantages

-

Accessories

The Rotary Vacuum Dryer, also referred to as Rotary Vacuum Paddle Dryer, is an ideal solution for chemical plants seeking efficient wet cake drying and solvent recovery of temperature-sensitive products. At Tech Mech Engineers, we offer a robust and rigid design that maximizes heat transfer and agitation to ensure optimal performance and trouble-free operation.

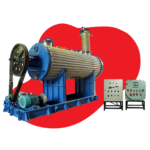

Our self-cleaning dust collector system improves solvent recovery efficiency and reduces costs by enabling reuse of solvents. We use TME customized Sealing to ensure a high level of vacuum, and the recovered material is suitable for manual handling, bagging, and dispatching. And we offer various unit and drive configurations tailored to your specific requirements, and the operation can be controlled by DCS/PLC to reduce manual intervention.

At Tech-Mech Engineers, we have manufactured Rotary Vacuum Dryers in a range of sizes, from 50 litres to 12 kilolitres, all functioning at optimum efficiency. We understand that every customer has unique requirements, which is why we offer customized solutions to meet your specific needs. Contact us to learn more about how we can tailor the Rotary Vacuum Dryer to your specific requirements.

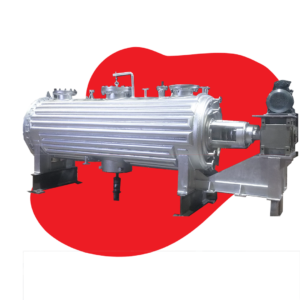

In addition to Rotary Vacuum Dryers, we also manufacture evaporative systems and heaters of various capacities and sizes.

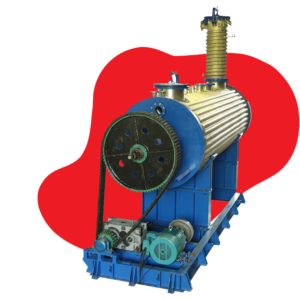

The Rotary Vacuum Dryer operates under vacuum, which allows for lower operating temperatures and reduces the risk of product degradation. The dryer consists of a horizontally mounted, cylindrical vessel with a rotating paddle shaft running through the length of the cylinder. The paddle shaft is designed with overlapping blades suitable for heating, that sweep the product over the heated surface of the cylinder, providing maximum exposure to the heat transfer surface.

The vacuum system is attached to the dryer, creating a vacuum inside the cylinder, which facilitates the removal of moisture and solvent from the product. As the product rotates in the dryer, the vacuum system draws off the moisture and solvent vapors from the surface of the product. The vapors are then condensed and collected in a condenser, and the solvent is recovered for reuse.

The dryer uses a central rotor to provide agitation and ensure uniform mixing and drying of the product. Any dust formation is arrested within a dust collector system. The solvent vapors are collected, cooled and stored in a receiver, while the dry product powder is discharged through a bottom valve.

By optimizing the heat transfer area, the overall turnaround time of the operation is reduced.

- Capacity: 50 liters to 12,000 liters

- Material of construction: Stainless steel or carbon steel with appropriate lining (as per customer’s requirement)

- Temperature range: Ambient to 200°C (higher temperature range is also available on request)

- Vacuum range: 760 to 1 Torr (or as per customer’s requirement)

- Agitation: Through central rotor with overlapping blades

- Dust collection: Self-cleaning dust collector system for solvent recovery and reduction in dust formation

- Sealing: TME Custom sealing for maintaining high level of vacuum or Mechanical seal

- Control system: DCS/PLC for automated control and reduction in manual intervention

- Drive system: Geared motor or variable frequency drive (VFD) as per customer’s requirement

- Safety features: Temperature and pressure sensors, emergency stop button, safety interlocks, and alarms

- Optional features: Nitrogen blanketing, CIP/SIP systems, jacketed vessel for heating/cooling, and explosion-proof design

Note: The technical specifications can vary depending on the specific requirements of the customer.

- High thermal efficiency

- Precise temperature control for drying heat-sensitive materials

- Vacuum operation for better color and texture of dried products

- Efficient rotary joint to inject heating media into agitator to remove condensation

- Pneumatic, hydraulic, and manual discharge valve options

- Quick opening discharge valve for easy cleaning and maintenance

- Sturdy stuffing box and mechanical seal design for shaft sealing

- Ability to handle granular and pasty materials

- Low temperature operation possible

With our Rotary Vacuum Dryer, you can enjoy the following benefits:

- Plug and play system for easy installation and use

- Operator safety ensured through various safety features, including overload protection

- Customizable rotor configuration to meet specific product and process requirements

In addition to the standard features of our Rotary Vacuum Dryer, we offer a range of accessories to enhance your operation and meet your specific requirements. These include:

Skid Mounted Units: For ease of installation and mobility, our Rotary Vacuum Dryer can be mounted on a skid, making it a portable unit that can be easily relocated as needed.

Pneumatic Valves: We offer pneumatic valves that can be operated remotely to provide precise control over the discharge of the dried product and the solvent recovery process.

Sampling Valves: Our sampling valves enable you to take representative samples of the product during the drying process, ensuring quality control and consistency.

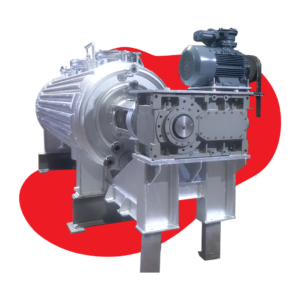

Direct Drive Configuration: For applications that require higher torque and more efficient power transmission, we offer a direct drive configuration that eliminates the need for belts and pulleys.

DCS / PLC Operation: Our Rotary Vacuum Dryer can be operated by a distributed control system (DCS) or programmable logic controller (PLC), allowing for automated and precise control of the drying process.

Mechanical Seal: Our mechanical seal ensures reliable and effective sealing of the shaft, preventing leaks and ensuring operator safety.

Fluid Coupling: We offer fluid couplings that provide smooth and efficient power transmission, reducing stress on the drive system and improving the longevity of the equipment.

Customization Options for Rotary Vacuum Dryer

At Tech-Mech Engineers, we offer a range of customization options to tailor our rotary vacuum dryer to your specific requirements, ensuring optimal performance & maximum efficiency.

Other products

With our cutting-edge technology and skilled workforce, we guarantee the highest level of quality in all our products.